Some users have had issues with the assisted leveling on their Replicator 5th Generation Printers. We have found that using a style similar to the 4th Generation manual leveling process is possible and provides very accurate leveling.

Note: Although the term leveling is used we are actually tramming the build plate so it is parallel to the XY Axis on the top. Both the XY Axis and the build plate don’t necessarily need to be level but instead must be true to one another.

To manually level the Replicator 5th Generation you will need a sheet of paper to help you determine your distance from the nozzle.

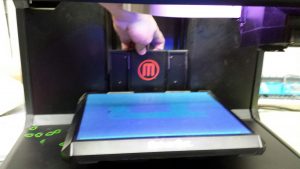

- The first step will be to manually move the build plate to just slightly below the nozzle height. Grabbing it as shown in the picture above allows you to raise the platform away from the bottom of the printer without effecting the build plate. After you make room under the platform then you can get your hand under far enough to push up on the same vertical piece you were pulling on.

- Reposition the nozzle to be in the location of the red dot on the build plate pictured above. This point is where the build plate hinges from. (To be more precise slide your build plate out and you will see the hinge point.)

- The next step is to place the sheet of paper on your build plate.

- Now you will move the sheet of paper back and forth feeling for friction between the nozzle and the build plate against the sheet of paper. As you are moving the sheet of paper you will turn the threaded Z-axis screw in order to raise the build plate in a controlled manner. Once you feel some friction on the paper stop turning the Z-Axis screw.

- At this point you will move the nozzle to a point directly above the right-side build plate adjustment screw. You will now use the sheet of paper to feel for friction at this point as well and adjust the right-side screw until you have the same amount of friction as the first location.

- Repeat step 5 at the front build plate adjustment screw.

- Your build plate should be level at this point so test the friction at a few other points on the build plate. If you have even pressure everywhere you are level, if not repeat steps 4-6 again and the build plate should continually become more and more level.